I-Rod® Strips

For elimination of corrosion problems at pipe supports

in conjunction with Deepwater Corrosion Inc.

I-Rod is a durable thermoplastic used to prevent corrosion problems at Pipe Supports

Product OverviewCorrosion at pipe supports is one of the leading causes of process piping failures. Not surprisingly, it is the beam supports and saddle clamps that have historically caused the majority of problems. They have the following undesirable features in common:

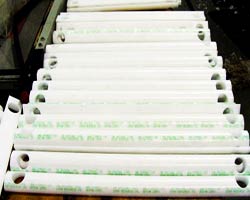

The solution is I-Rod. I-Rod is a durable thermoplastic, extruded and cut into a half round rod. It is the key component in all of Deepwater’s I-Rod brand pipe supports. It is available in 10 foot lengths, or cut-and-drilled (which mirrors the Nu-Bolt™ assembly component.) for use with standard size pipe U-bolts. There are three different diameter sizes for I-Rod (0.75 in, 1 in, and 1.5 in) as well as a high-temperature version for process piping that operates above 200 °F ApplicationsBeam and Saddle supports Beam dressing |

I-Rod is available in 10 ft. lengths or pre-cut-and-drilled for any standard pipe U-bolt.

|

Main BenefitsHalf-round shapeThe half-round shape minimizes contact between the pipe and the support, eliminating the crevice. Keeping water out keeps corrosion at bay. Maintenance I-Rod also provides an electrically isolated stand-off between the pipe and the supporting beam or saddle clamp. This allows for easy maintenance and inspection, while preventing galvanic corrosion between dissimilar metals (the pipe and support). Durability I-Rod also has excellent compressive strength and a very low friction coefficient. This makes I-Rod ideal as a beam dressing, and pipe damage during new construction is reduced when I-Rod is present to assist in pipe fitting. Be aware of imposters Other products used to mimic I-Rod have been the cause of many problems. Each batch of authentic I-Rod has a batch number printed directly on the surface, and only licensed Deepwater agents like Alduco are authorized to sell I-Rod. Go to www.stoprust.com for a list of approved agents. |

This imposter product fails under the weight of the pipe,

others may be crushed completely.